When I first started working as a network engineer and later as a NOC chief, I thought the stress was just part of the job. At the time, we didn’t have network automation in place. Everything was done by hand, device by device, ACL by ACL, line by line. On paper, that sounds manageable.

In practice, it was chaos.

I was dealing with a global backbone—100 to 150 routers and other devices across multiple global regions and security enclaves. A single misstep could create ripple effects that spanned continents. I would triple-check my work, then pull in another engineer to look it over, then check it again before pressing “enter.” Even then, there were moments when I had no choice but to push the change and hope for the best.

There’s a phrase we used back then: “full send.” It basically meant, “we’ve done everything we can—now let’s see what happens.” That’s not exactly the kind of confidence you want running critical infrastructure. But it was the reality of operating without automation.

Living in the Manual Era

The manual approach created three major challenges that still stick with me today:

- Sheer Scale: My day-to-day involved configuring 100+ devices by hand. That’s hundreds of opportunities for typos, copy-paste errors, or mis-applied configs. Multiply that across a global network and the risk curve grows fast.

- Coordination Chaos: It wasn’t just my network. Often, I had to work with other teams and organizations to pass traffic across their networks too. That meant long chains of emails: “Hey, I need these ACLs applied to these interfaces by this time.” If my wording wasn’t perfect or if someone on the other side misread it, traffic didn’t flow. And when traffic didn’t flow, I was the one getting the call at 2 a.m.

- Endless Validation: Because every change carried so much risk, we checked and re-checked everything. Sometimes that meant hours of peer review for a single ACL change. Other times it meant frantically troubleshooting why packets were disappearing into a blackhole somewhere in the backbone or peering back through previous Technical Service Orders (approved Change Requests)

As a junior engineer, it was a trial-by-fire environment. You learned quickly, but every day felt like a test you could fail spectacularly.

How Automation Changed Everything

The first time I used automation, it felt like magic. Suddenly, I wasn’t typing out the same commands over and over again. Scripts did the repetitive work for me. Instead of relying on a colleague’s gut check, I could run automated validations that confirmed my changes wouldn’t break connectivity.

Here’s what shifted for me:

- Reliability: Automation removes human inconsistency. Configurations were applied the same way every time, no matter who was executing them.

- Speed: Tasks that once consumed half a day—like validating a change across dozens of devices—were done in minutes.

- Collaboration: Automation created a shared language. Instead of negotiating ACLs in endless email threads, we had workflows and scripts everyone could understand and trust.

But the biggest change wasn’t technical—it was psychological. For the first time, I wasn’t holding my breath every time I pushed a change. I had confidence. I trusted the system to catch mistakes before they made it to production.

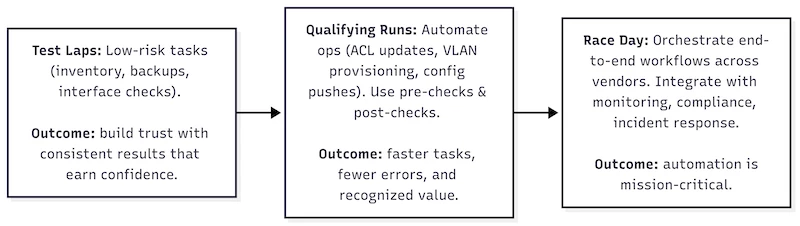

How to Adopt Network Automation: Test Laps, Qualifying Runs, Race Day

If you’re wondering how to make this shift, my advice is simple: don’t try to win the Indy 500 on your first day behind the wheel. Think of adopting automation like preparing for a race: you start with test laps, work your way up through qualifying runs, and only then are you ready for race day.

Test Laps: Build Trust with Low-Risk Tasks

At this stage, you’re still in the pit lane, running practice laps to make sure the car even stays on the track. Start with simple, low-risk automations: pulling inventory data, validating backups, and checking interface status. These early efforts don’t decide the race, but they build confidence in the “engine.”

The key is to show your team and leadership that automation delivers consistent, accurate results. Every time a script catches an error or saves time, you’re proving it’s safe to let automation out of the garage.

Qualifying Runs: Automate Day-to-Day Operations

Once you’ve proven automation won’t stall out, it’s time to push harder. Now you can automate routine operational tasks like ACL updates, VLAN provisioning, or standardized config pushes. Always pair them with pre-checks and post-checks so everyone knows the lap is clean. Reality check: if you think that this is a one-man job, get that out of your head; you can’t be an automation lone wolf. At a minimum, you’re going to need three other like-minded teammates to manage what success looks like ( you don’t know everything in the beginning).

This is when leadership will start to notice. Suddenly, you’re shaving minutes — even hours — off tasks. Mistakes drop, and engineers are freed up to focus on higher-value work. Just like qualifying, this stage earns you a spot on the grid. It shows the team you’re not just experimenting — you’re ready to perform.

Race Day: Make Automation Mission-Critical

When you’ve reached this stage, automation isn’t just a tool in the trunk — it’s the engine powering the entire race. You’re orchestrating end-to-end workflows across vendors and platforms, integrating automation into monitoring, compliance, and even incident response.

On race day, every decision, every pit stop, every lap is informed by automation. It’s no longer optional. It’s the only way to stay competitive at speed.

Best Practices That Helped Me

Along the way, a few lessons stuck with me:

- Get leadership on board early. Executives respond to data. Show them concrete numbers—time saved, outages prevented, fewer escalations.

- Invest in training. Instead of training and coding sessions, organize happy hours and socials to share tools and playbooks, encouraging a culture of learning.

- Don’t boil the ocean. Incremental wins are more valuable than big, risky projects that never deliver

- Celebrate milestones. The first time your team successfully automates a production change? Treat it like a podium finish. Recognition fuels momentum.

Why Automation Matters More Than Ever

Back when I was cutting my teeth, the networks were big, but nothing like what operators face today. Hybrid cloud. Multi-vendor environments. Overlapping overlays on top of overlays. The complexity curve keeps climbing, and manual operations simply can’t keep up.

If you’re still managing everything by hand, you’re living on borrowed time. You might get away with it for a while, but sooner or later, the combination of scale, complexity, and human error will catch up with you.

Automation isn’t just about making life easier. It’s about survival. It’s about protecting yourself, your team, and your organization from the inevitable mistakes that come with manual work.

The Bottom Line

Looking back, I don’t miss the trial-by-fire culture. I don’t miss holding my breath every time I hit enter on a command line. What I do value is the confidence automation gave me: the confidence that my changes would work as intended, the confidence that I could sleep through the night without worrying about a mis-typed ACL, the confidence that I was building a network I could trust.

For me, automation turned chaos into confidence. And for today’s network operators, it can do the same.

Don’t treat automation as a luxury. Treat it as the baseline.

Resources to Adopt Network Automation

Community Articles:

Books

Online Resources

- https://www.geeksforgeeks.org/ - Provides tutorials, articles, coding challenges, and resources to learn programming.

- https://www.pluralsight.com/ - An online learning platform offering tech-focused courses and hands-on labs.